Installation of a solid fuel boiler

Solid Fuel Boiler Installation

A solid fuel boiler can be a dependable way to heat your home or small commercial property using fuels such as wood logs, coal, or briquettes. When it is installed correctly, you get steady heat, predictable running costs, and a system that can work well with radiators and hot water cylinders. Because solid fuel appliances involve high temperatures and chimney draft, the quality of the installation is just as important as the boiler you choose.

We provide a complete installation service, from assessing your current heating setup to commissioning the boiler and explaining safe day to day operation. Our approach focuses on correct sizing, safe flue routing, reliable circulation, and practical access for loading and cleaning. If you are upgrading from an older boiler or adding a new heat source to an existing system, we will plan the job to keep disruption low and performance high.

What is included in our installation service

Every property is different, so we start with an on site assessment and clear recommendations. We check your heat demand, existing pipework, chimney condition, and where the boiler can be installed safely. You will receive a straightforward plan that covers the boiler position, flue approach, safety components, and how the boiler will connect to your current heating circuit.

- System assessment and sizing to match boiler output to the property and avoid overheating or poor efficiency.

- Boiler positioning and hearth requirements so clearances, ventilation, and service access meet practical safety needs.

- Flue and chimney checks including draft considerations, suitable liners when required, and safe routing.

- Pipework connections for flow and return, hot water integration, and tidy, serviceable isolations.

- Safety and control components such as relief protection, correct expansion arrangements, and reliable circulation planning.

- Commissioning including pressure checks, leak testing, control setup, and a test burn to confirm stable operation.

If your wider system needs attention at the same time, we can coordinate related heating services such as radiator balancing, pump replacement, or control upgrades so the new boiler performs as intended.

Planning, safety, and compliance

Solid fuel boilers produce intense heat and require consistent airflow and dependable heat removal. We pay close attention to boiler room ventilation, safe distances from combustible materials, and secure fuel storage practices. Where the installation ties into an existing central heating layout, we also review how heat will circulate during power loss scenarios and how the system will be protected against over temperature conditions.

Flue performance is essential. A poor chimney can lead to smoke spillage, weak draft, and soot buildup. We assess chimney suitability, recommend lining where needed, and ensure that joints, access points, and clean out provisions are practical for ongoing maintenance. Our goal is to deliver an installation that is safe, easy to use, and straightforward to maintain over the long term.

Integration with radiators and hot water

Many customers want the boiler to serve both space heating and domestic hot water. We design the connection to work smoothly with your cylinder and radiator circuit, using properly sized pipe runs and suitable controls to manage heat distribution. If you already have another heat source, we can advise on compatible options for combined operation and how to avoid unwanted back feeding or temperature swings.

For property owners comparing options, we can also discuss broader boiler installation services and how a solid fuel system differs from other boiler types in terms of storage, daily operation, and maintenance expectations.

How the installation process works

- Site visit and consultation to review your current system, chimney, and preferred fuel type.

- Proposal and schedule with an outline of materials, timescales, and any preparatory work required.

- Preparation including isolating the old appliance if present and protecting work areas.

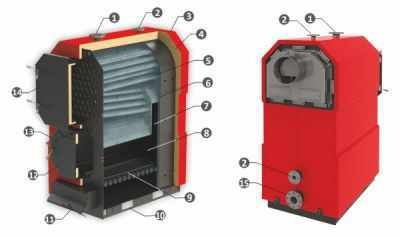

- Installation of the boiler, flue connections, pipework, and safety components.

- Commissioning and testing to confirm stable draft, correct circulation, safe temperatures, and leak free operation.

- Handover with clear guidance on lighting, refuelling, ash removal, and recommended cleaning intervals.

We keep you informed throughout the job and we do not leave until the system is operating as expected. Before we finish, we confirm that you can use the controls confidently and that you understand safe fuel handling and storage.

Aftercare and maintenance support

Solid fuel systems work best when they are cleaned and checked regularly. Chimneys and heat exchangers can accumulate soot and tar, which reduces efficiency and can affect safe operation. We can advise on a practical maintenance routine and the signs that indicate your boiler needs attention, such as reduced output, increased smoke, or unusual smells.

- Guidance on daily and weekly cleaning tasks to keep airflow and heat transfer consistent.

- Checks of seals, doors, and grate components that experience wear.

- Advice on fuel quality and storage to reduce smoke and buildup.

- Support with related hvac maintenance services when your system includes pumps, controls, or radiator circuits that also need periodic care.

If you are considering a new solid fuel boiler or replacing an older unit, contact us to arrange an assessment and we will recommend an installation approach that prioritizes safety, comfort, and reliable performance.

FAQ

What do you need to check before installing a solid fuel boiler?

We assess heat demand, chimney condition, available ventilation, and the current pipework layout. We also confirm there is enough space for safe clearances, servicing access, and practical fuel storage.

Can a solid fuel boiler work with my existing radiators and hot water cylinder?

Yes, in most cases it can be integrated into an existing central heating system. We design the pipework, controls, and safety protection so heat is distributed correctly and hot water is supplied reliably.

How often does a solid fuel boiler need maintenance?

Basic cleaning is often needed weekly or more frequently during heavy use, especially ash removal and checking air paths. A deeper inspection of seals, heat exchanger surfaces, and flue performance should be done regularly to maintain efficiency and safe operation.