Replacing a shut-off valve

Shut Off Valve Replacement

A working shut off valve lets you control water to a tap, toilet, appliance, or the whole property in seconds. When a valve is stuck, leaking, or unreliable, even a small plumbing issue can turn into a major disruption. Replacing a faulty valve is a straightforward upgrade that improves safety, reduces the risk of water damage, and makes future repairs faster and cleaner.

Whether you have an older stopcock, an under sink isolation valve, or a valve behind a toilet that will not close fully, we replace it with a modern, dependable fitting. We work carefully to protect cabinets, flooring, and pipework, and we always test the new valve under pressure before we leave.

When a Shut Off Valve Should Be Replaced

Some valves can be serviced, but many problems are signs it is time for a replacement, especially with older fittings. If you are unsure, we can assess the condition and recommend the safest option as part of our plumbing inspection services.

- Valve will not turn due to corrosion, mineral buildup, or a seized spindle.

- Valve turns but does not stop water, often caused by worn internal washers or damaged seats.

- Leaks around the stem or from the body, even after gentle tightening.

- Drips at compression joints from tired olives, distorted pipe ends, or vibration.

- Old gate valves that offer poor shut off reliability compared to modern quarter turn valves.

- Emergency preparedness where you want quick, certain shut off for a rental or family home.

If you have an active leak, turning off the main supply and arranging emergency plumbing services can prevent further damage while the valve is replaced.

Our Replacement Process

Replacing a shut off valve is not only about swapping a part. It requires choosing the correct valve type, ensuring compatibility with your pipe material, and making leak free joints that will hold long term. Our approach prioritizes safety, neat workmanship, and reliable isolation.

1. Site check and safe isolation

We identify what the valve controls and confirm the best isolation point, either at the internal stopcock or an external shut off where available. We relieve pressure and drain down the relevant section so the pipe is safe to work on. If the existing valve fails to isolate fully, we use appropriate methods to control water while we complete the change.

2. Selecting the right valve

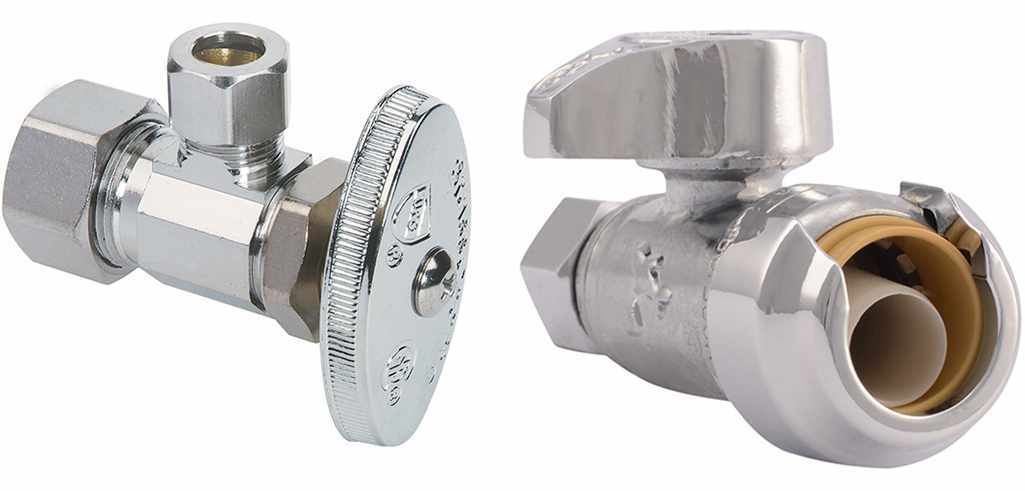

We match the replacement to your setup, considering pipe size and material, access limitations, and the required flow. Common options include quarter turn ball valves, isolation valves for appliances, and service valves under basins. Where space allows, we may recommend upgrading to a more accessible valve for easier future maintenance.

3. Removal and installation

We remove the old valve with care to avoid twisting or stressing nearby pipework. Depending on your system, we may work with compression fittings, threaded connections, or soldered joints. We then install the new valve, align it correctly, and ensure it can be operated comfortably without fouling on cabinets or walls.

4. Testing and finishing

Once installed, we slowly restore water supply and check for leaks at working pressure. We test the valve for smooth operation and full shut off, then recheck after a short run to confirm everything remains dry. The area is cleaned up and we explain what was replaced and how to operate the new valve.

Types of Shut Off Valves We Replace

Different parts of a property use different valves. If you are not sure what you have, a photo or quick description is usually enough for us to advise before we arrive.

- Main stopcock for isolating the entire property water supply.

- Under sink isolation valves for hot and cold feeds to taps.

- Toilet isolation valves to stop water to the cistern for repairs.

- Appliance valves for washing machines, dishwashers, and fridge water lines.

- Outdoor shut off valves for garden taps and external lines.

- Heating and ancillary valves where water isolation is needed for related plumbing work.

Why Choose Us for Valve Replacement

A shut off valve is a small component with a big job. Poor installation can lead to slow drips, sudden leaks, and damage behind cabinets that goes unnoticed. We focus on durable materials, correct fitting methods, and thorough testing.

- Careful workmanship with attention to nearby pipework and finishes.

- Clear communication on what needs replacing and why.

- Upgrades where beneficial, including easier to reach quarter turn valves.

- Support for related issues such as worn flexi hoses or minor pipe adjustments.

If your valve problem is part of a broader issue, we can coordinate it as part of our plumbing repair services so everything is resolved in one visit where possible.

What You Can Do Before We Arrive

If you suspect a leaking or failing valve, a few simple steps can reduce risk. If you cannot safely do these, leave everything as it is and contact us.

- Locate the main stopcock and confirm you can access it.

- Remove items from under sinks or around the valve to provide working space.

- If there is an active leak, place a container and protect nearby electrics and cupboards.

- Avoid forcing a seized valve, since it can snap or start leaking heavily.

Replacing a shut off valve is a practical investment in control and peace of mind, and we are ready to help you restore dependable isolation wherever you need it.

FAQ

How do I know if my shut off valve is failing?

Common signs include a valve that will not turn, a handle that turns but does not fully stop the water, or moisture around the stem or fittings. If you see recurring dampness or corrosion, replacement is usually the most reliable fix.

Will the water need to be turned off to replace the valve?

Yes, the affected line must be isolated and depressurised to work safely. In most cases we shut off the main supply briefly, replace the valve, then restore water and test for leaks.

Can you upgrade my old stopcock to a quarter turn valve?

In many properties, yes. A quarter turn valve is easier to operate and provides more dependable shut off, especially in emergencies. We will confirm pipe size, access, and the best fitting method before proceeding.